High-performance gaskets for the industry.

- Offer

- Materials

- Types

- Ordering

At GMP-TEHNIK, we take pride in our wide range of seals, which includes over 150 standard profiles.

We manufacture seals ranging from 5mm to 550mm, and for larger sizes, we can deliver within seven days.

In addition to our standard seal program, we can also create custom seals based on your drawings and/or samples.

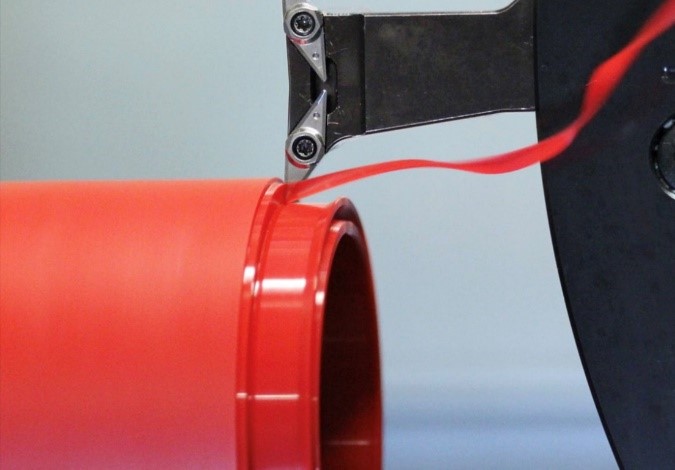

The production of seals/gaskets is carried out using the Seal-Jet technology on CNC machines, which represents the latest concept in seal production using parametrically programmed CNC machines and does not require the use of molds.

We manufacture high-quality and precise seals of all standard profiles from various types of materials in quantities of one or more pieces.

Naša brtvena rješenja izrađena su od visokokvalitetnih materijala koji pružaju izvrsne karakteristike i performanse. S našom bogatom paletom materijala, možemo osigurati da brtve zadovolje različite potrebe i zahtjeve, uključujući visoke temperature, otpornost na kiseline, trenje i habanje, kao i druga fizikalna opterećenja.

Naša ponuda zaptivača obuhvata različite tipove brtvila, svaki dizajniran za specifične potrebe i funkcije u vašim strojevima i uređajima.

S-zaptivači klipnjače: Ovi zaptivači se koriste za brtvljenje klipnjače i osiguravaju pouzdano zaptivanje tokom rotacije i oscilacije.

K-seals for pistons: Designed for sealing pistons in cylinders, these seals ensure efficient sealing and protection against leakage.

A-wipers: These wipers are designed to remove debris and dirt from the surface of the piston, ensuring its smooth and trouble-free operation.

F-guide rings: These rings serve as guides for the piston and ensure the stability of the piston within the cylinder.

St-support rings: These rings are designed to support the piston in the cylinder and prevent unwanted movement and wear of the piston.

R-rotary seals: These seals enable the rotation of the shaft with minimal friction and energy loss.

To ensure that we provide you with the perfect seal that meets your needs, please follow this simple procedure:

Working medium: Please provide us with the type of working medium that the seal will come into contact with. It can be hydraulic oil, engine oil, air, or any other medium.

Function Information: Please define the function or installation location of the seal in your system. We need to know whether sealing of the piston, piston rod, wiper, O-ring, or any other type of seal is required.

Seal Profile: Please choose the seal profile that suits your needs - it can be a standard profile or you can provide a drawing of a specific profile that we need to manufacture. Groove Dimensions: If you have specific dimensions of the installation space or groove, please clearly define them. Additionally, you can send us a sample of the original seal if available.

Working Parameters: Please provide relevant working parameters such as pressure, temperature, and speed of the piston movement. These details will assist us in selecting the appropriate materials and designing the seal that will best meet your requirements.

In addition to our standard seal program, we can also create custom seals based on your drawings and/or samples.